Rohrleitungsbau

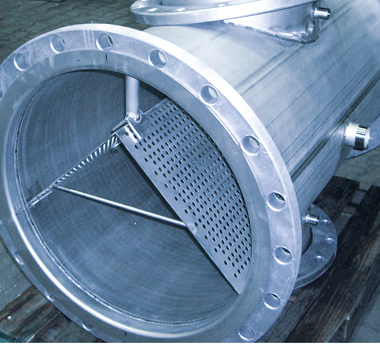

Die Abteilung Rohrleitungsbau hat Ihre Stärke im Anlagenbau. Hier werden bei uns im Werk in Meppen Rohrkomponenten vorgefertigt und dann in kurzer Zeit in den Anlagen montiert. Ferner werden auch Wartungsarbeiten durchgeführt.

Da wir im Besitz der Zulassung AD 2000 HP0/HPO 100 R ist, sind Arbeiten an Rohrleitungen im Hochdruckbereich, sowie an Druckbehältern kein Problem.

Wir halten geprüfte Schweißer nach DIN EN 287 und Verfahrensprüfungen nach DIN EN ISO 15614 für verschiedene Materialien, Wandstärken

und Schweißpositionen vor.

Beim Rohrleitungsbau verfolgen wir ebenfalls das Konzept möglichst große Spools in der eigenen Vorfertigung zu produzieren und im Anschluss zu montieren. Hiermit können die Montagetätigkeiten und somit Stillstandzeiten möglichst gering gehalten werden.

Die Erstellung von Isometrien erfolgt mittels eines CAD-Programmes.